Why this Jeep boiled over at 218 degrees after radiator replacement

Recently, I had a lovely experience trying to figure out why a 2018 Jeep Cherokee kept boiling over at 218 degrees Fahrenheit. Thankfully, the solution was stupid simple, but I wasted a LOT of time figuring it out.

Background

Vehicle: 2018 Jeep Cherokee Latitude Plus with the 3.2L V6 engine

Reason for repair: The stock radiator had a big crack in the driver’s side, causing a sizeable leak. I replaced the radiator and the vehicle performed great after the repair was completed. No leaks, no overheating, all is well. Then, 1 month passes and the customer sends me a video of it boiling over….uh-oh.

Diagnosis and process

After hearing and seeing the customer’s concern, I dove into service information and real-world experiences from other shops to figure out what I could be dealing with. I saw several examples of the coolant reservoir cap failing, causing a lack of pressure within the system, leading to a boil-over condition. Okay, sweet, simple enough, so I ordered a new cap. I then thought back on the job and remembered that the system previously had green coolant, when Jeep specifically calls for violet or purple OAT or HOAT coolant. I put the correct coolant in after my repair, but I started to think maybe there was more green left in the system than I anticipated, so I also ordered more coolant to do another complete flush on the vehicle.

Fast forward to the customer dropping off the vehicle, I first performed a visual inspection to make sure no other leaks developed in the meantime. I also inspected the coolant bottle because they are notorious for cracking. Thankfully, I did not find anything new and obvious, so I continued on with the process I planned for.

I flushed the system twice with new, purple coolant, and then did a final fill. I replaced the coolant cap with the new one I ordered and began the bleeding process.

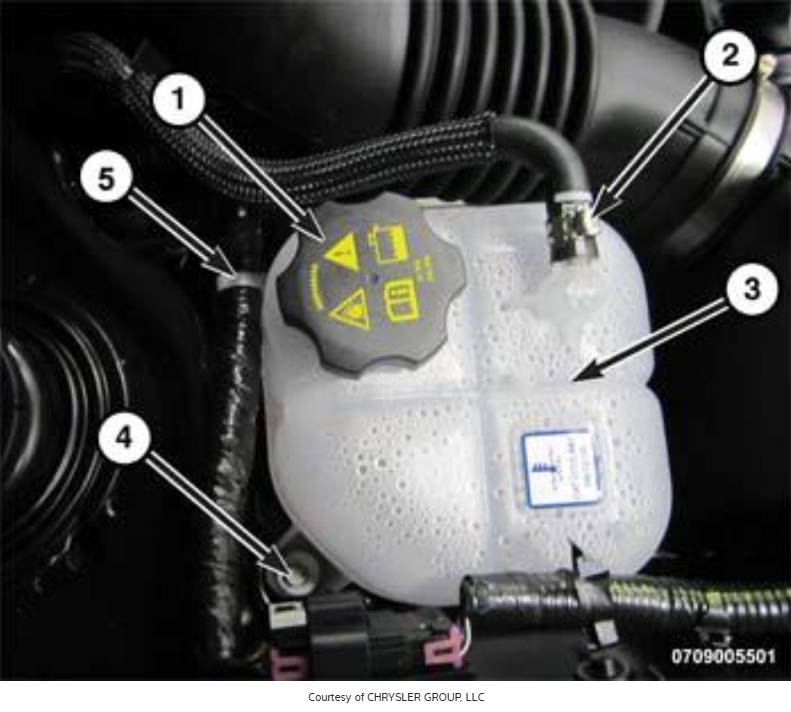

This is known as the “Expansion Tank” in an FCA system. I refer to it as a coolant bottle, tomato tomato.

Now, to be clear, I did not have a Coolant Vacuum Filling Tool, so I was trying to bleed the system manually by cracking several “bleed” locations around the coolant system. This was a massive mistake, but I carried on in ignorance, thinking that I would be able to get all the air out of the system with conventional methods. I struggled for hours heating the vehicle up, squeezing hoses to get air out, and topping the reservoir off, but my efforts proved worthless. No matter what I tried, the coolant would boil and overflow out of the coolant bottle at 218 degrees on the dot. Every. Single. Time.

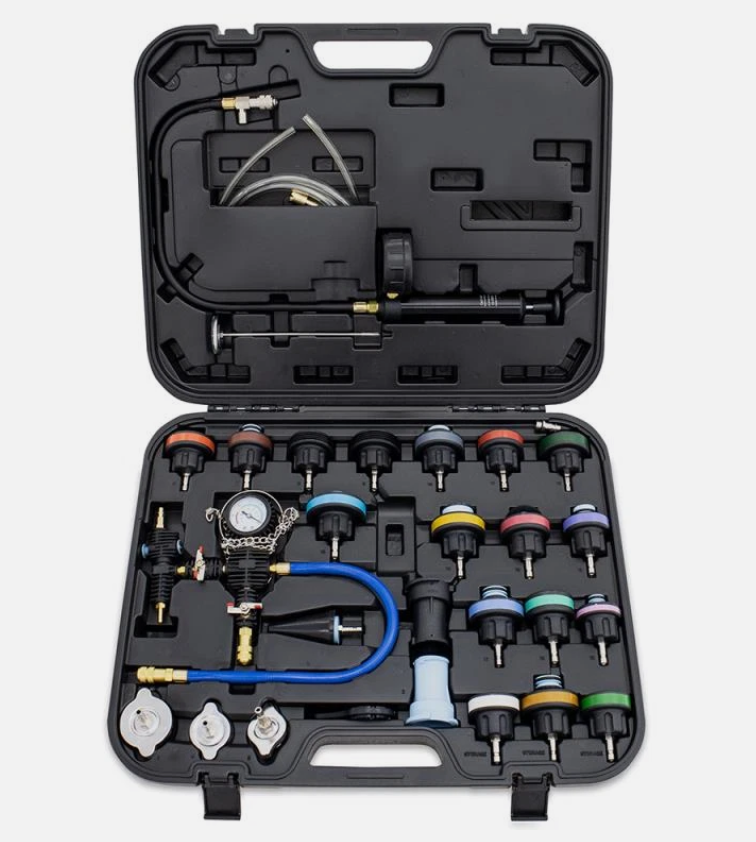

After these few hours of frustration, I decided that I needed to get my hands on a vacuum filling tool, because there had to be air in the system that I could not get out. Since I needed it ASAP, I called up a Technician Friend of mine and he graciously let me borrow his kit for the afternoon (thank you very much Jon, if you read this).

With proper tool in hand, I vacuumed the system and added another half-gallon of coolant. This means there was a “half-gallon” of air trapped in that system…no wonder it wouldn’t hold pressure. This little breakthrough put some more wind in my sails and I happily turned the vehicle on to heat it up and see if it would boil over again.

This is the Mishimoto 28-piece Coolant Pressure and Vacuum Purge kit. You can find it here (not sponsored, just a killer kit)

To my great frustration and agony, it boiled over right at 218F. What in the world is going on??

I scratched my head and stared at the vehicle for a bit, thinking of every possibility I had not already addressed. Then, I remembered seeing posts about other technicians using aftermarket caps on these coolant systems and having them fail right out of the box. Apparently, aftermarket caps just don’t seal very well on these bottles for whatever reason.

Full of skepticism, I removed the aftermarket cap I had just installed and I re-installed the OEM cap. I started the vehicle and watched it intently as it heated up.

205F…..210F…..215F……The moment of truth….220F, no coolant boiling over, all coolant hoses are firm, and finally the radiator fans started turning on and off.

Finally, after a long afternoon full of frustration, this Jeep was finally running like it should. Thank goodness.

Moral of the Story/TL;DR

The coolant bottle cap was never the issue; air trapped in the system due to my incomplete bleeding process was.

Others’ experience and other resources convinced me that I was able to bleed the system without the special tools I now know are required.

While gravity bleeding conventional coolant systems is simple, I must say I much prefer this vacuum-filling method much better. Since this Jeep, I have purchased a 28-Piece Mishimoto Coolant System Fill/Test Kit for use on other jobs and it makes the process SO MUCH FASTER.

So, if you are working on an FCA or expansion tank-style coolant system, get a proper vacuum filler and thank me later.

Oh, and go OEM for the coolant cap; aftermarket options are garbage.